Special coating technique originally developed by Tanazawa Hakkosha, which is to be applied on mainly grained surface of injection moulds. G COAT is applicable on any mould, as long as heat curing is applicable.

Features

-

Reduction of whiting/ghosting etc.

Improves the appearance on the parts by restraining slight scuffs so-called whiting, clouds or ghosting

-

Painted appearance

Gives plastics a painted appearance, and process of painting the parts might be skipped

-

Applicable without changing original grain structure

Only G Coat can be removed and re-coated

Other advantages

- Coating layer is extremely thin - 20 um or less

- Heating temperature is low and does not damage the steel

- Applicable either on running and existing tools

- There are few limitations on tool dimensions

Sample

-

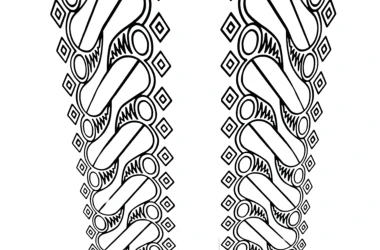

Leather grain + G coat (molded with PP)

Without G coat. With G coat

Creating a texture surface on a material by using compressed air to blast abrasive particles against it.

Spray etching is a surface treatment process in which ink containing controlled particle sizes is sprayed onto a mold surface using a spray gun, following a specific texture or pattern requirement.

Photo etching is the process of using ultra-violet light to fix an image onto a sheet of metal, and then using chemicals to etch the shape into the metal, removing more and more of the material until only the shape is left.